Highly effective simplicity

The HCR collaborative robots, in contrast to industrial robots, is characterized by ease of programming and excellent flexibility of adaptation, necessary to perform various tasks related to short, medium and high volume production.

The ease of programming is comparable to the simplicity of the smartphone – after just a few dozen minutes of training, you can easily program them based on the principle of “teaching by showing” and an intuitive graphical interface. They are able to work safely with a human being without the need to use specialized barriers or safety cages.

✔ Easy to master

✔ Intuitive graphical interface

✔ 3High precision 24/7

Multifunctional with precision

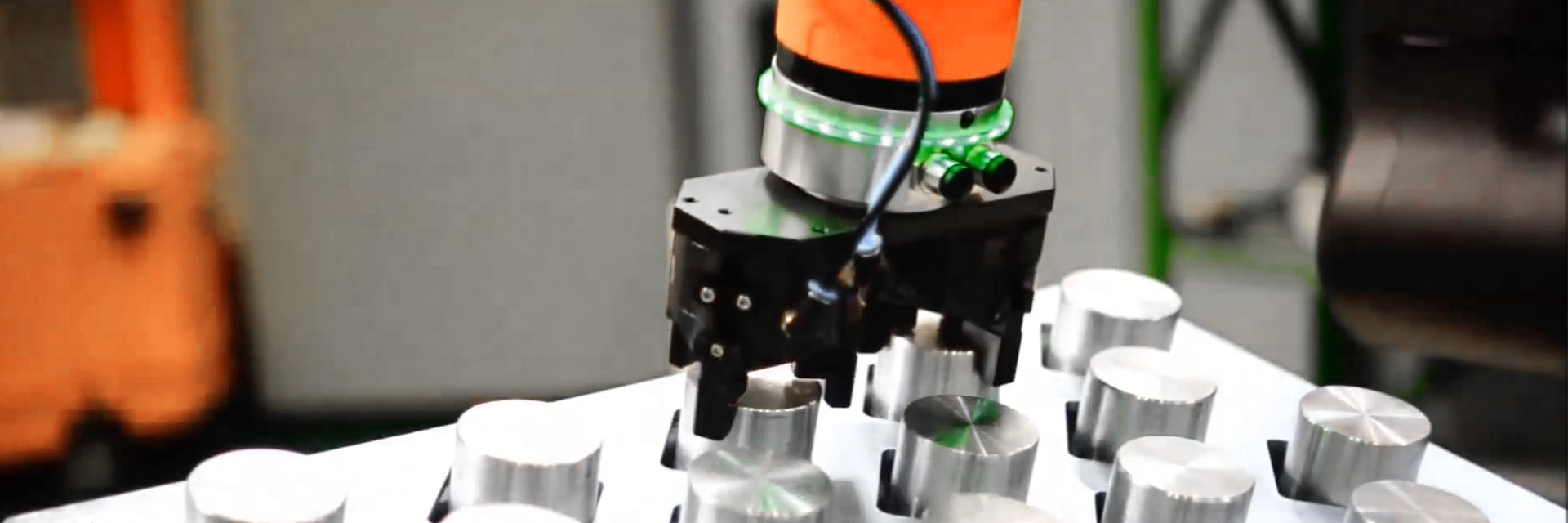

Collaborative robot so-called Cobot, allows high precision to work 24 hours, 7 days a week in monotonous, dangerous activities, ensuring 100% repeatability and high quality of work. Thanks to the ease of programming and the speed of implementation, the collaborating HCR robots become useful in the implementation of tasks not yet available for robots in low and medium serial production. HCR is a robot cooperating for hard work in industrial conditions, where proven solutions are of key importance.

As collaborative robots gain widespread adoption across various industries, the demand for peripheral robotics’ accessories will grow in tandem. Hanwha recognizes this, and the vital importance towards fast and easy deployment of robotics solutions. We look forward to working with Industrial partners for grippers, vision systems, torque sensors and other applications.

Compact size and fast set-up enables

Easy to master

After a 100 years of Mass Production – where one size fits all – customers’ needs are diversifying and product lifecycle is getting shorter. Manufacturing line changes its production more frequently due to higher mix, smaller batch production. But no need to call an external expert nor change entire production line.

With its compact body and flexible mounting option, HCR offers the fast set-up, and thanks to its easy programming solution, there is no need of hiring expert to re-programming the robot.

Ontdek de HCR producten

Designed for user’s convenience

The LED light on wrist lets you see at a glance the status of the robot, including normal operation, collision detection, or direct teaching mode. Tool I / O and EtherCAT port at the end of the robot eliminates the need for complicated cabling by allowing external tools to be attached directly.

HCR’s robot software, Rodi, has pre-compatibility with major vision vendors, allowing users to easily integrate robot and vision systems. (Supports major vision products such as Omron, Cognex, Keyence, Baumer and etc.) In particular, Rodi has additional commands to make it easier to set up for tasks such as loading, palletizing, and conveyor trekking, which are frequently used in robotic applications and are cumbersome to program.

It is safe to install the robot right next to the operator as robot stops when it detects an external collision, also the virtual safety fence can be set in advance to prevent collision. Human can concentrate on high-value added work which requiring judgment ability while robot does repetitive and dangerous work. It allows to prevent the accident and optimize the production line through process automation. Also, since there is no need to separate the space for robot application, it allows optimal use of space.

Meer informatie aanvragen